2.3: The Juran Trilogy

- Page ID

- 39479

\( \newcommand{\vecs}[1]{\overset { \scriptstyle \rightharpoonup} {\mathbf{#1}} } \)

\( \newcommand{\vecd}[1]{\overset{-\!-\!\rightharpoonup}{\vphantom{a}\smash {#1}}} \)

\( \newcommand{\id}{\mathrm{id}}\) \( \newcommand{\Span}{\mathrm{span}}\)

( \newcommand{\kernel}{\mathrm{null}\,}\) \( \newcommand{\range}{\mathrm{range}\,}\)

\( \newcommand{\RealPart}{\mathrm{Re}}\) \( \newcommand{\ImaginaryPart}{\mathrm{Im}}\)

\( \newcommand{\Argument}{\mathrm{Arg}}\) \( \newcommand{\norm}[1]{\| #1 \|}\)

\( \newcommand{\inner}[2]{\langle #1, #2 \rangle}\)

\( \newcommand{\Span}{\mathrm{span}}\)

\( \newcommand{\id}{\mathrm{id}}\)

\( \newcommand{\Span}{\mathrm{span}}\)

\( \newcommand{\kernel}{\mathrm{null}\,}\)

\( \newcommand{\range}{\mathrm{range}\,}\)

\( \newcommand{\RealPart}{\mathrm{Re}}\)

\( \newcommand{\ImaginaryPart}{\mathrm{Im}}\)

\( \newcommand{\Argument}{\mathrm{Arg}}\)

\( \newcommand{\norm}[1]{\| #1 \|}\)

\( \newcommand{\inner}[2]{\langle #1, #2 \rangle}\)

\( \newcommand{\Span}{\mathrm{span}}\) \( \newcommand{\AA}{\unicode[.8,0]{x212B}}\)

\( \newcommand{\vectorA}[1]{\vec{#1}} % arrow\)

\( \newcommand{\vectorAt}[1]{\vec{\text{#1}}} % arrow\)

\( \newcommand{\vectorB}[1]{\overset { \scriptstyle \rightharpoonup} {\mathbf{#1}} } \)

\( \newcommand{\vectorC}[1]{\textbf{#1}} \)

\( \newcommand{\vectorD}[1]{\overrightarrow{#1}} \)

\( \newcommand{\vectorDt}[1]{\overrightarrow{\text{#1}}} \)

\( \newcommand{\vectE}[1]{\overset{-\!-\!\rightharpoonup}{\vphantom{a}\smash{\mathbf {#1}}}} \)

\( \newcommand{\vecs}[1]{\overset { \scriptstyle \rightharpoonup} {\mathbf{#1}} } \)

\( \newcommand{\vecd}[1]{\overset{-\!-\!\rightharpoonup}{\vphantom{a}\smash {#1}}} \)

Dr. Joseph Juran (1904-2008)

Dr. Joseph Juran was one of the foremost experts in the area of quality. Juran believed that to achieve quality, you must start with organizational goals, policies, and vision. Converting organizational goals into results is accomplished through three managerial processes called the JURAN TRILOGY: Quality Planning, Quality Control, and Quality Improvement (The Juran Institute, 2016). To learn more about Juran, visit the Juran Institute.

Quality Planning

“Quality does not happen by accident; it must be planned.” Quality planning is the structured process of designing products and services to meet new goals and ensure that customer needs are met.

Quality Planning Steps:

- Establish the project.

- Identify customers.

- Discover the customer’s needs.

- Develop the product.

- Develop the process.

- Develop the controls and transfer to Operations.

Quality Control

Quality control is a universal managerial process for conducting operations to provide stability, to prevent adverse change, and to "maintain the status quo." Quality control can also be described as "a process for meeting the established goals by evaluating and comparing actual performance and planned performance and taking action on the difference."

The quality control process:

- Choose a control subject.

- Establish Measurement.

- Establish Standards of Performance.

- Measure Actual Performance.

- Compare to Standards (interpret the difference).

- Act on the difference.

Quality Improvement

"All improvement takes place project by project." Quality improvement is the process of creating breakthrough levels of performance by eliminating wastes and defects to reduce the cost of poor quality.

Steps to Quality Improvement:

- Prove the need for improvement.

- Identify the improvement projects.

- Establish project improvement teams.

- Provide project teams with resources.

Juran’s Fitness for Use

Quality begins with whom, how, and why customers will use a product; all improvement activities should be customer-focused. Juran’s fitness for use definition of quality means the product should be a good price, work well for the customer, be distributed efficiently from the producer to the customer, and be supported efficiently by the company. Juran’s four components of product fitness:

- Quality of Design: A successful company conducts market research and creates satisfied customers by building their needs into the product design. The quality of design must also consider the intended functions of the product and the type of conditions in which it will perform. Another consideration affecting the quality of the design is cost. How much will it cost to make the product?

- Quality of Conformance: Does the manufacturing process adhere to specifications? Attention to conformance can be a vital tool and decrease the cost of manufacturing as it reduces the likelihood of these types of catastrophic failures.

- Availability: In the customer's view, availability and reliability are often synonymous. For example, if a customer attempts to order a laboratory instrument only to find out that the product is out-of-stock and will be on backorder for a month, his level of customer satisfaction goes down. Quality, as it relates to availability, can be a matter of maintaining inventory and ensuring availability as in the above example, and it can also be an issue of speedy shipping and have a good distribution infrastructure.

- Field Service: Field service personnel are, typically, the technicians who deliver, install, and set up products, providing training to the customer on proper use and maintenance.

Philip Crosby (1926-2001)

Philip Crosby was an American-born author and business executive, noted for his contributions to the management of "quality crises." He is credited with effecting a 30% reduction in costs incurred through scrap waste when he served as the lead quality control manager for the Pershing Missile program. Later in his career, when the U.S. manufacturing industry faced a quality crisis and stiff competition from the Japanese, he responded with the creation of the DIRFT principle. Short for "doing it right the first time."

Crosby’s DIRFT philosophy on quality:

- Quality means conformance to requirements.

- Quality systems should focus on the prevention of nonconformance.

- The performance target should be "zero defects."

- The cost of nonconformance should be the standard by which quality is measured.

Ultimately, Crosby's guiding principle was that robust quality assurance systems pay for themselves in the end and are more than worth whatever initial costs a company must absorb to establish such a system. Additional insight into his philosophies can be found in his first published book; Quality is Free.

Dr. Kaoru Ishikawa (1915-1989)

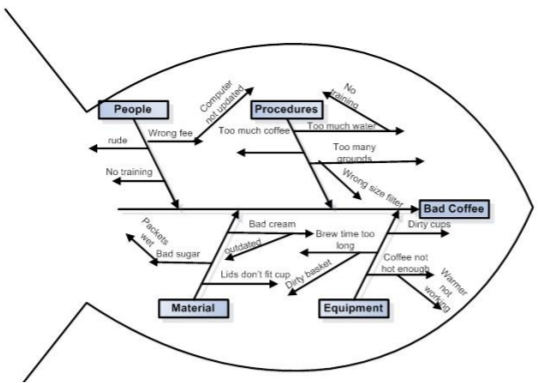

Dr. Kaoru Ishikawa is best known for his creation of the "Fishbone Diagram" or "cause and effect diagram." This type of chart is used in an evaluation of industrial processes to investigate the potential root-cause of an identified issue. In the example on the left is an Ishikawa fishbone diagram to investigate the cause of bad coffee. Here, people, procedures, material, and equipment are all identified as potential causes as branches from the backbone (bad coffee). An Ishikawa diagram is helpful to visualize the interrelated causality “cause and effect” in various processes used to create a product.

The Fishbone diagram is not Ishikawa’s only innovation in the area of quality. He also introduced the idea of "quality circles." A quality circle is a volunteer group of individuals within a company who are trained to analyze and solve work-related problems, sharing their insights with upper management. This quality circle theory was a direct shoot-off from Deming's Plan-Do-Act-Check cycle. It should be noted that Dr. Ishikawa was intimately familiar with Deming's work, and many of his contributions to quality philosophy arose as a direct result of his lifelong work in synthesizing and expanding Deming's ideas into Japanese corporate culture.

Dr. Genichi Taguchi (1924-2012)

Dr. Genichi Taguchi was a Japanese engineer and statistician known for his development of the ‘Taguchi Methods’, which represents a type of statistical methodology for improving quality in the manufacturing process. Many industrial statisticians in the U.S. are coming to accept his ideas after years of resistance. There are two key philosophies from the Taguchi Method that stand out as representative of his views on quality. The first is that poor quality represents a loss to society, not just the individual consumer. The nature of this loss can be calculated using any number of loss functions to derive a real number cost from a variable (the Taguchi method uses the “mean-squared-error” approach).