2.2: Quality Pioneers

- Page ID

- 39478

Good quality management techniques are as numerous and varied as the types of biotechnology companies that use them. Most companies will lean towards a ‘favored' quality philosophy, but few rely on just one. It is much better to draw from several schools thought. We will present some of the major contributors to the field of quality below. You are encouraged to research more on these pioneers' interesting backgrounds!

Dr. Walter Shewhart (1891-1967)

Dr. Walter Shewhart developed statistical methods that are applied to improve quality processes that provide both goods and services. While at Bell Laboratories, Dr. Shewhart was the first to encourage the use of statistics to identify, monitor, and determine the source of variation found in repetitive processes. His work was to target and remove sources of variation.

Dr. Shewhart recognized two sources of variation in a process: controlled and uncontrolled variation. Controlled variation is internal to the process and is also referred to as common causes. In an uncontrolled variation, the source is external to the process and known as assignable causes. Dr. Shewhart believed that once a process is under control process is predicable.

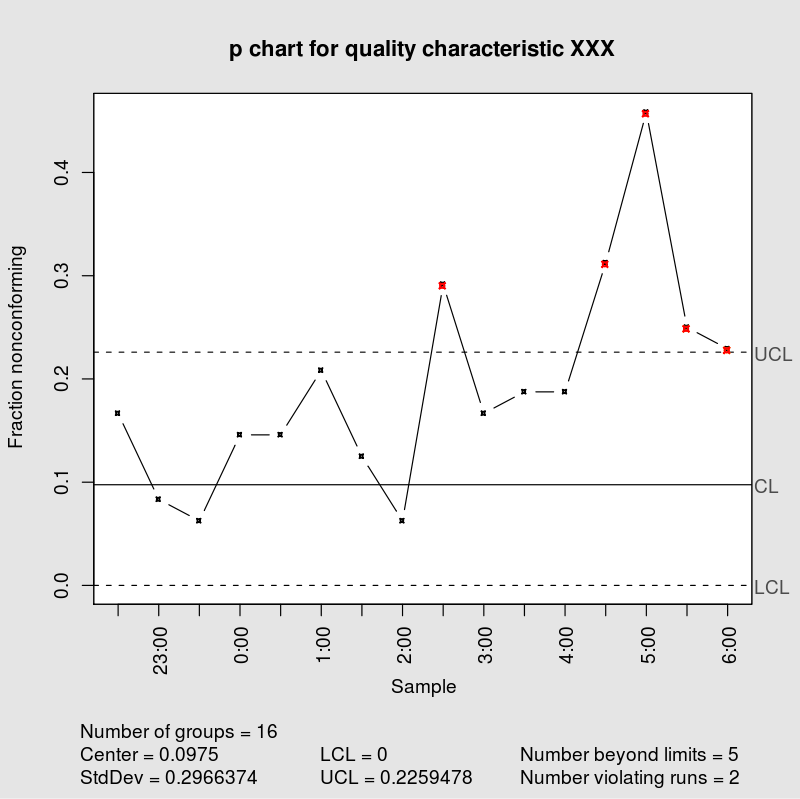

The most influential contribution of Dr. Shewhart is statistical process control charts. These charts provide a framework for monitoring the behavior of a manufacturing process and provide feedback to help an organization improve the process. In figure 2.1 is a p-chart tracking the number of non-conforming units in a sample. The red dots indicate points that are outside allowable quality parameter. To learn more about the seven basic tools of quality control: https://en.Wikipedia.org/wiki/Control_chart

Dr. W. Deming (1901-1993)

Dr. W. Deming was one of the preeminent figures in the quality control profession. Deming worked as a consultant to the U.S. War Department during World War II. After the war, he adapted the technique he had developed for quality improvement in the War Department to private industry. This method centers on statistical controls on manufacturing processes and cooperation between management and labor. Deming believed that most quality problems were generated by management and created a philosophy to facilitate quality improvement in a company through better management.

Mass inspection of the product was replaced by statistical methods, extensive training of personnel, and two-way communication between the workers and management. Deming pushed for a cooperative atmosphere between the employees and management by increasing the employee's status through encouraging participation in solving problems and giving the training to facilitate this. The W. Edwards Deming Award for Quality is a national award presented annually in Japan to the company that has demonstrated the greatest quality improvement effort and to the individual who has been responsible for the most significant quality improvement.

Plan-Do-Check-Act Cycle

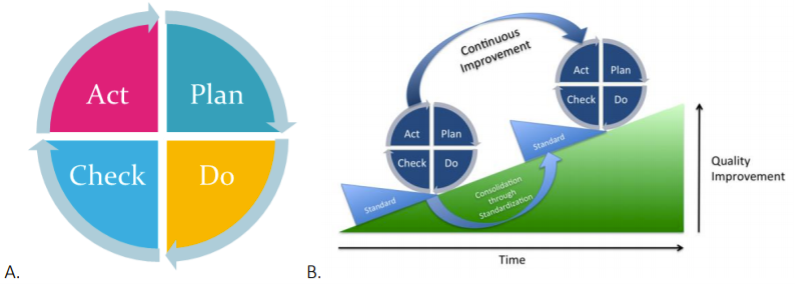

Popularized by Deming, the Plan-Do-Act (PDCA) Cycle, also known as the Shewhart Cycle, is a four-step process for quality improvement and can be used as a model for improvement of a current project or when starting a new improvement project. The PDCA is based on the scientific method, and an updated version of the cycle will sometimes include “observation” (OPDCA) for emphasis on the concept that observation is what led to starting the process for improvement and is a cycle for continuous improvement.

- PLAN: The first step is to develop a plan to effect improvement. What are the objectives and desired results? What are the resources that can be used to implement the plan?

- DO: In the second step (do), a small-scale plan is carried out. Data is collected to see how the plan worked.

- CHECK: In the third step (check), the data collected in the DO phase is evaluated for effectiveness. Here is where a gap analysis can be performed. Data is frequently graphed for trend analysis.

- ACT: Sometimes called adjust, the last step (Act), an action is taken to effect change in the process. Are there are any disparities between the Plan and Do? Root cause analysis is helpful at this phase. At this step, you use what is learned to tackle new improvement projects, and the cycle continues.

Test Your Knowledge!

Using your results/grade from your first homework grade, create a Plan-Do-Check-Act Cycle for improving your study approach.