11.2: Waste Reduction

- Page ID

- 69459

\( \newcommand{\vecs}[1]{\overset { \scriptstyle \rightharpoonup} {\mathbf{#1}} } \)

\( \newcommand{\vecd}[1]{\overset{-\!-\!\rightharpoonup}{\vphantom{a}\smash {#1}}} \)

\( \newcommand{\dsum}{\displaystyle\sum\limits} \)

\( \newcommand{\dint}{\displaystyle\int\limits} \)

\( \newcommand{\dlim}{\displaystyle\lim\limits} \)

\( \newcommand{\id}{\mathrm{id}}\) \( \newcommand{\Span}{\mathrm{span}}\)

( \newcommand{\kernel}{\mathrm{null}\,}\) \( \newcommand{\range}{\mathrm{range}\,}\)

\( \newcommand{\RealPart}{\mathrm{Re}}\) \( \newcommand{\ImaginaryPart}{\mathrm{Im}}\)

\( \newcommand{\Argument}{\mathrm{Arg}}\) \( \newcommand{\norm}[1]{\| #1 \|}\)

\( \newcommand{\inner}[2]{\langle #1, #2 \rangle}\)

\( \newcommand{\Span}{\mathrm{span}}\)

\( \newcommand{\id}{\mathrm{id}}\)

\( \newcommand{\Span}{\mathrm{span}}\)

\( \newcommand{\kernel}{\mathrm{null}\,}\)

\( \newcommand{\range}{\mathrm{range}\,}\)

\( \newcommand{\RealPart}{\mathrm{Re}}\)

\( \newcommand{\ImaginaryPart}{\mathrm{Im}}\)

\( \newcommand{\Argument}{\mathrm{Arg}}\)

\( \newcommand{\norm}[1]{\| #1 \|}\)

\( \newcommand{\inner}[2]{\langle #1, #2 \rangle}\)

\( \newcommand{\Span}{\mathrm{span}}\) \( \newcommand{\AA}{\unicode[.8,0]{x212B}}\)

\( \newcommand{\vectorA}[1]{\vec{#1}} % arrow\)

\( \newcommand{\vectorAt}[1]{\vec{\text{#1}}} % arrow\)

\( \newcommand{\vectorB}[1]{\overset { \scriptstyle \rightharpoonup} {\mathbf{#1}} } \)

\( \newcommand{\vectorC}[1]{\textbf{#1}} \)

\( \newcommand{\vectorD}[1]{\overrightarrow{#1}} \)

\( \newcommand{\vectorDt}[1]{\overrightarrow{\text{#1}}} \)

\( \newcommand{\vectE}[1]{\overset{-\!-\!\rightharpoonup}{\vphantom{a}\smash{\mathbf {#1}}}} \)

\( \newcommand{\vecs}[1]{\overset { \scriptstyle \rightharpoonup} {\mathbf{#1}} } \)

\(\newcommand{\longvect}{\overrightarrow}\)

\( \newcommand{\vecd}[1]{\overset{-\!-\!\rightharpoonup}{\vphantom{a}\smash {#1}}} \)

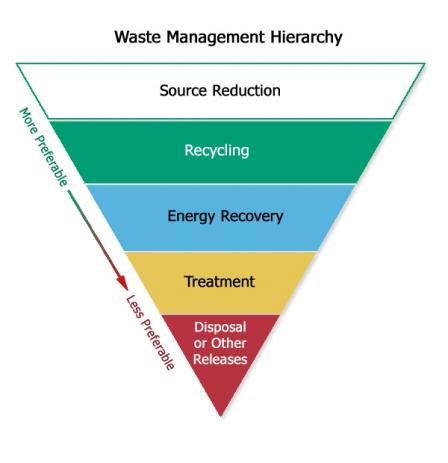

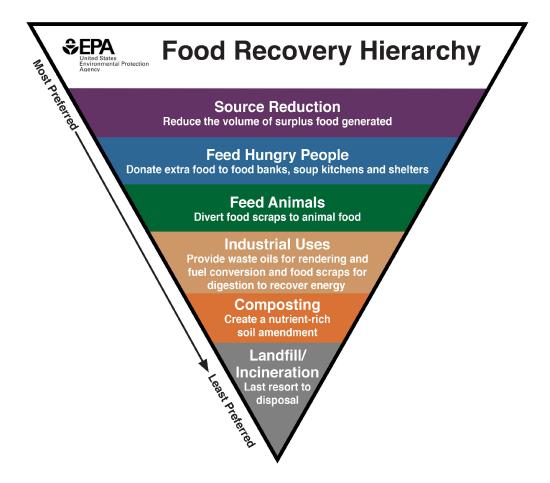

\(\newcommand{\avec}{\mathbf a}\) \(\newcommand{\bvec}{\mathbf b}\) \(\newcommand{\cvec}{\mathbf c}\) \(\newcommand{\dvec}{\mathbf d}\) \(\newcommand{\dtil}{\widetilde{\mathbf d}}\) \(\newcommand{\evec}{\mathbf e}\) \(\newcommand{\fvec}{\mathbf f}\) \(\newcommand{\nvec}{\mathbf n}\) \(\newcommand{\pvec}{\mathbf p}\) \(\newcommand{\qvec}{\mathbf q}\) \(\newcommand{\svec}{\mathbf s}\) \(\newcommand{\tvec}{\mathbf t}\) \(\newcommand{\uvec}{\mathbf u}\) \(\newcommand{\vvec}{\mathbf v}\) \(\newcommand{\wvec}{\mathbf w}\) \(\newcommand{\xvec}{\mathbf x}\) \(\newcommand{\yvec}{\mathbf y}\) \(\newcommand{\zvec}{\mathbf z}\) \(\newcommand{\rvec}{\mathbf r}\) \(\newcommand{\mvec}{\mathbf m}\) \(\newcommand{\zerovec}{\mathbf 0}\) \(\newcommand{\onevec}{\mathbf 1}\) \(\newcommand{\real}{\mathbb R}\) \(\newcommand{\twovec}[2]{\left[\begin{array}{r}#1 \\ #2 \end{array}\right]}\) \(\newcommand{\ctwovec}[2]{\left[\begin{array}{c}#1 \\ #2 \end{array}\right]}\) \(\newcommand{\threevec}[3]{\left[\begin{array}{r}#1 \\ #2 \\ #3 \end{array}\right]}\) \(\newcommand{\cthreevec}[3]{\left[\begin{array}{c}#1 \\ #2 \\ #3 \end{array}\right]}\) \(\newcommand{\fourvec}[4]{\left[\begin{array}{r}#1 \\ #2 \\ #3 \\ #4 \end{array}\right]}\) \(\newcommand{\cfourvec}[4]{\left[\begin{array}{c}#1 \\ #2 \\ #3 \\ #4 \end{array}\right]}\) \(\newcommand{\fivevec}[5]{\left[\begin{array}{r}#1 \\ #2 \\ #3 \\ #4 \\ #5 \\ \end{array}\right]}\) \(\newcommand{\cfivevec}[5]{\left[\begin{array}{c}#1 \\ #2 \\ #3 \\ #4 \\ #5 \\ \end{array}\right]}\) \(\newcommand{\mattwo}[4]{\left[\begin{array}{rr}#1 \amp #2 \\ #3 \amp #4 \\ \end{array}\right]}\) \(\newcommand{\laspan}[1]{\text{Span}\{#1\}}\) \(\newcommand{\bcal}{\cal B}\) \(\newcommand{\ccal}{\cal C}\) \(\newcommand{\scal}{\cal S}\) \(\newcommand{\wcal}{\cal W}\) \(\newcommand{\ecal}{\cal E}\) \(\newcommand{\coords}[2]{\left\{#1\right\}_{#2}}\) \(\newcommand{\gray}[1]{\color{gray}{#1}}\) \(\newcommand{\lgray}[1]{\color{lightgray}{#1}}\) \(\newcommand{\rank}{\operatorname{rank}}\) \(\newcommand{\row}{\text{Row}}\) \(\newcommand{\col}{\text{Col}}\) \(\renewcommand{\row}{\text{Row}}\) \(\newcommand{\nul}{\text{Nul}}\) \(\newcommand{\var}{\text{Var}}\) \(\newcommand{\corr}{\text{corr}}\) \(\newcommand{\len}[1]{\left|#1\right|}\) \(\newcommand{\bbar}{\overline{\bvec}}\) \(\newcommand{\bhat}{\widehat{\bvec}}\) \(\newcommand{\bperp}{\bvec^\perp}\) \(\newcommand{\xhat}{\widehat{\xvec}}\) \(\newcommand{\vhat}{\widehat{\vvec}}\) \(\newcommand{\uhat}{\widehat{\uvec}}\) \(\newcommand{\what}{\widehat{\wvec}}\) \(\newcommand{\Sighat}{\widehat{\Sigma}}\) \(\newcommand{\lt}{<}\) \(\newcommand{\gt}{>}\) \(\newcommand{\amp}{&}\) \(\definecolor{fillinmathshade}{gray}{0.9}\)The waste management hierarchy lists processes to address waste in order of preference with the goals of limiting waste, minimizing environmental impact, and maximizing additional benefits (such as electricity generation or production of recycled goods). It is symbolized as an upside triangle, meaning that the largest volume of waste should be handled using the first process (most preferred), and the smallest volume should be handled using the last process (least preferred). These processes in order of preference are reduction, recycling, energy recovery (such as incineration), treatment, and disposal (figure \(\PageIndex{a}\)). Individuals can exercise the first two processes by applying the four R's (see below). Unfortunately, the U.S. and the world overall, handles a large volume of waste using the least preferred method (disposal). As previously mentioned, about half of municipal solid waste (MSW) goes to a sanitary landfill for disposal. In contrast, only 23.5% of municipal solid waste (MSW) was recovered and recycled and another 8.5% was composted in 2018. Waste stream percentages also vary widely by region. As an example, San Francisco, California recycles or composts 80% of its waste material, whereas Houston, Texas recycles or composts only 19%.

Figure \(\PageIndex{a}\): Left: The waste management hierarchy lists processes for handling waste from most to least preferable. They are source reduction, recycling, energy recovery, treatment, and disposal or other releases. Right: The food recovery hierarchy is a waste management hierarchy specific to food waste. It begins with source reduction (reduce the volume of surplus food generated). Next is feed hungry people (donate extra food to food banks, soup kitchens, and shelters. Third is feed animals (divert food scraps to animal food. Fourth is industrial uses (provide waste oils for rendering and fuel conversion and food scraps for digestion to recover energy. Fifth is composting (create a nutrient-rich soil amendment). The remaining waste goes to landfill or incineration as a last resort to disposal. Images by EPA (public domain).

The ideal waste management alternative is to prevent waste generation in the first place. Hence, waste prevention is a basic goal of all the waste management strategies. Numerous technologies can be employed throughout the manufacturing, use, or post-use portions of product life cycles to eliminate waste and, in turn, reduce or prevent pollution. Some representative strategies include environmentally conscious manufacturing methods that incorporate less hazardous or harmful materials, the use of modern leakage detection systems for material storage, innovative chemical neutralization techniques to reduce reactivity, or water saving technologies that reduce the need for fresh water inputs.

Source reduction (waste minimization) refers to the strategies that minimize the amount of generated waste and/or reduce the toxicity of the resultant waste when designing or manufacturing products or services. Waste can be reduced by reusing materials, using less hazardous substitute materials, or by modifying components of design and processing. Source reduction in manufacturing not only saves resources, but it also reduces costs for the manufacturer and indirectly for the consumer. For example, minimal packaging reduces material use, increases distribution efficiency, and reduces fuel consumption and resulting air emissions. Similarly, building materials can be designed to reduce the overall mass of material needed for a given structure.

The dry cleaning industry provides an excellent example of product substitution to reduce toxic waste generation. For decades, dry cleaners used tetrachloroethylene, or "perc" as a dry cleaning solvent. Although effective, tetrachloroethylene is a relatively toxic compound. Additionally, it is easily introduced into the environment, where it is highly recalcitrant due to its physical properties. Further, when its degradation occurs, the intermediate daughter products generated are more toxic to human health and the environment. Because of its toxicity and impact on the environment, the dry cleaning industry has adopted new practices and increasingly utilizes less toxic replacement products, including petroleum-based compounds. Further, new emerging technologies are incorporating carbon dioxide and other relatively harmless compounds. While these substitute products have in many cases been mandated by government regulation, they have also been adopted in response to consumer demands and other market-based forces.

Recycling refers to recovery and reprocessing of useful materials such as glass, paper, plastics, wood, and metals from the waste stream so they may be incorporated into the fabrication of new products. Recycling reduces the need of natural resource exploitation for raw materials, but it also allows waste materials to be recovered and utilized as valuable resource materials. Recycling of wastes reduces energy consumption and emissions generated by extraction of virgin materials and their subsequent manufacture into finished products, reduces overall energy consumption and greenhouse gas emissions that contribute to the global climate change, and reduces the incineration or landfilling of the materials that have been recycled. Moreover, recycling creates several economic benefits, including the potential to create job markets and drive growth. The success of recycling depends on effective collection and processing of recyclables, markets for reuse (e.g. manufacturing and/or applications that utilize recycled materials), and public acceptance and promotion of recycled products and applications utilizing recycled materials.

Numerous examples of successful recycling and reuse efforts are encountered every day. In some cases, the recycled materials are used as input materials and are heavily processed into end products. Common examples include the use of scrap paper for new paper manufacturing, or the processing of old aluminum cans into new aluminum products. In other cases, reclaimed materials undergo little or no processing prior to their re-use. Many construction materials can be reused, including concrete, asphalt materials, masonry, and reinforcing steel. "Green" plant-based wastes are often recovered and immediately reused for mulch or fertilizer applications. Many industries also recover various byproducts for reuse. In some cases, the recycled materials are used as input materials and are heavily processed into end products. Common examples include the use of scrap paper for new paper manufacturing, or the processing of old aluminum cans into new aluminum products. In other cases, reclaimed materials undergo little or no processing prior to their reuse. Some common examples include the use of tree waste as wood chips, or the use of brick and other fixtures into new structural construction. In any case, the success of recycling depends on effective collection and processing of recyclables, markets for reuse, and public acceptance and promotion of recycled products and applications utilizing recycled materials.

The Four R's

The four R's (refuse, reduce, reuse, and recycle) are strategies that allow individuals to limit the volume and negative impacts of the waste they generate. They resemble the waste management hierarchy, but focus at the individual scale rather than the scale of a company or waste management system. They are listed in order of most to least environmentally beneficial, and they are all better alternatives than discarding trash into the landfill. Recycling is last because it requires energy to reprocess waste.

To refuse is to decline products or processes that harm the environment if you do not need them. Choosing products without packaging is an example of refusing. To reduce is to choose products or processes with lower ecological footprint (the area of land required to produce them). Examples include products with limited packaging or durable items rather than flimsy or disposable ones. Reuse refers to using a product multiple times or finding an alternative use for it. For example, one could share, borrow, or rent items. A plastic yogurt or pudding container could be repurposed for storage or gardening. As noted above, recycling means to return used items to be reprocessed (figure \(\PageIndex{b}\)). Commonly recycled materials include cardboard, glass, cans, and certain plastics.

Figure \(\PageIndex{b}\): Recycling, or returning materials to be reprocessed, is the last of the four R's. If items cannot be refused, reduced, or reused, recycling is a better alternative than discarding into the landfill. Image by Intel Free Press (CC-BY).

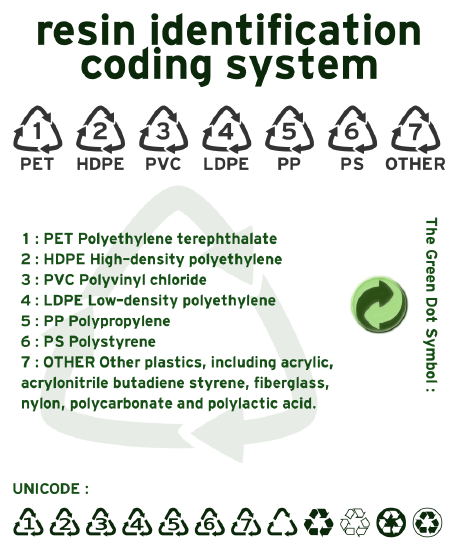

Resin identification codes are the triangular symbols on recyclable plastics that indicate their composition (figure \(\PageIndex{c}\)). A variety of materials make up plastics, and they are not all recycled the same way. Furthermore, your local recycling service may recycle some types of plastics but not others. Plastics with codes 1 and 2 are commonly recycled. For the codes, check with your local recycling service. Local businesses may house collection bins for plastics that are not commonly recycled. For example, grocery stores commonly have receptacles for recycling plastic bags, which fall under code 4.

Figure \(\PageIndex{c}\)): The resin identification coding system explains the chemical composition of various plastics. Some are commonly recycled, and others are not. The text in the image is, "1: PET Polyethylene terephthalate, 2: HDPE High-density polyethylene, 3: PVC Polyvinyl chloride, 4: LDPE Low-density polyethylene, 5: PP Polypropylene, 6: PS Polystyrene, 7: OTHER Other plastics, including acrylic, acrylonitrille butadiene styrene, fiberglass, nylon, polycarbonate and polylactic acid. Image by Filtre/OpenClipart Library (public domain).

Interactive Element

Which items can be recycled is based on where you live and the waste management service available there. The Environmental Protection Agency provides general recycling guidelines. You local waste collector may provide an interactive website to help you determine which items to recycle. For example Recology, which serves Northern California, has a searchable website called What Bin.

Biological Treatment

Landfill disposal of wastes containing significant organic fractions is increasingly discouraged in many countries, including the United States. Such disposal practices are even prohibited in several European countries. Since landfilling does not provide an attractive management option, other techniques have been identified. One option is to treat waste so that biodegradable materials are degraded and the remaining inorganic waste fraction (known as residuals) can be subsequently disposed or used for a beneficial purpose.

Biodegradation of wastes can be accomplished by using aerobic composting, anaerobic digestion, or mechanical biological treatment (MBT) methods. If the organic fraction can be separated from inorganic material, aerobic composting or anaerobic digestion can be used to degrade the waste and convert it into usable compost (figure \(\PageIndex{d}\)). For example, organic wastes such as food waste, yard waste, and animal manure that consist of naturally degrading bacteria can be converted under controlled conditions into compost, which can then be utilized as natural fertilizer. Food scraps and yard waste together currently make up more than 30% of what we throw away and could be composted instead. Making compost keeps these materials out of landfills where they take up space and release methane, a potent greenhouse gas that contributes to climate change. Composting can be done at an industrial scale, such as with yard waste collected from homes in a city. It can also be done at home.

Figure \(\PageIndex{d}\)): Compost is a nutrient-rich substance formed from decomposition of yard and food waste that enriches garden soil. Image by EPA (public domain).

Compost material may be used in a variety of applications. Compost enriches soil, helping retain moisture and suppress plant diseases and pests. Furthermore, It reduces the need for chemical fertilizers and encourages the production of beneficial bacteria and fungi. In addition to its use as a soil amendment for plant cultivation, compost can be used remediate soils, groundwater, and stormwater. Composting can be labor-intensive, and the quality of the compost is heavily dependent on proper control of the composting process. Inadequate control of the operating conditions can result in compost that is unsuitable for beneficial applications. Nevertheless, composting is becoming increasingly popular; composting diverted 82 million tons of waste material away the landfill waste stream in 2009, increased from 15 million tons in 1980. This diversion also prevented the release of approximately 178 million metric tons of carbon dioxide in 2009 – an amount equivalent to the yearly carbon dioxide emissions of 33 million automobiles.

All composting requires three basic ingredients: browns, greens, and water. "Browns" are materials such as dead leaves, branches, and twigs. "Greens" are materials such as grass clippings, vegetable waste, fruit scraps, and coffee grounds. The brown materials provide carbon for your compost, the green materials provide nitrogen, and the water provides moisture to help break down the organic matter. A compost pile should have an equal amount of browns to greens. Layers of these organic materials with different particle sizes should be alternated.

Aerobic composting is accomplished by placing selected proportions of organic waste into piles, rows or vessels, either in open conditions or within closed buildings fitted with gas collection and treatment systems. During the process, bulking agents such as wood chips are added to the waste material to enhance the aerobic degradation of organic materials. Finally, the material is allowed to stabilize and mature during a curing process where pathogens are concurrently destroyed. The end-products of the composting process include carbon dioxide, water, and the usable compost material.

In some cases, aerobic processes are not feasible. As an alternative, anaerobic processes may be utilized. Anaerobic digestion consists of degrading mixed or sorted organic wastes in vessels under anaerobic conditions. The anaerobic degradation process produces a combination of methane and carbon dioxide (biogas) and residuals (biosolids). Biogas can be used for heating and electricity production, while residuals can be used as fertilizers and soil amendments. Anaerobic digestion is a preferred degradation for wet wastes as compared to the preference of composting for dry wastes. The advantage of anaerobic digestion is biogas collection; this collection and subsequent beneficial utilization makes it a preferred alternative to landfill disposal of wastes. Also, waste is degraded faster through anaerobic digestion as compared to landfill disposal.

Backyard composting requires a compost bin or pile to be placed in dry, shady spot near a water source (figure \(\PageIndex{e}\)). Brown and green materials are added as they are collected, and larger pieces are chopped or shredded before they are added to the pile. Dry materials are moistened as they are added. Once the compost pile is established, grass clippings and green waste are mixed into the pile when added. When fruit and vegetable wastes are added, they are buried under 10 inches of compost material. Some homeowners cover the top of the compost with a tarp to keep it moist. When the material at the bottom is dark and rich in color, the compost is ready to use. This usually takes anywhere between two months to two years.

Figure \(\PageIndex{e}\)): This compost bin contains food scraps and yard waste. Image by Ben_Kerckx/Pixabay (Pixabay license)

For those who do not have the space for an outdoor compost pile, materials can be composted indoors using a special type of bin, which can be purchased at a local hardware store, gardening supplies store, or made at home. Care must be taken to properly manage the compost pile and keep track of what is added such that it does not attract pests or rodents or smell bad. The compost should be ready in two to five weeks.

Interactive Element

Not all food scraps can go into compost. If you want to start a compost pile and are not sure which food scraps are suitable, see the lists on the Environmental Protection Agency website.

Attribution

Modified by Kyle Whittinghill and Melissa Ha from the following sources:

- Systems of Waste Management from Sustainability: A Comprehensive Foundation by Tom Theis and Jonathan Tomkin, Editors (CC-BY). Download for free at CNX.

- Composting at Home. Environmental Protection Agency. Accessed 01-18-2021 (public domain).

- 15.2 Waste Management Strategies from Essentials of Environmental Science by Kamala Dorsner and CK-12 (CC-BY)